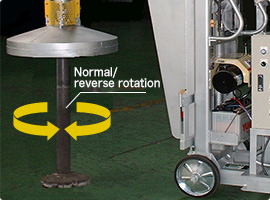

Nikkei MC Aluminium's molten metal cleaning equipment Shizunami maintains an extremely smooth molten metal surface by the normal/reverse rotation system of the shaft, reducing generation of oxides due to engulfment and performing degassing effectively.

It is possible to design the equipment according to the customer's conditions of use. Please feel free to contact us.